The following article was originally published in Manure Manager. Click here to read it in its original form.

| Productivity and economics of nurse trucks for manure transport | |

| Written by Tim Harrigan | |

|

The profitability of livestock operations depends upon the ability to efficiently recycle manure nutrients and reduce commercial fertilizer use. Record-high fertilizer prices have created an incentive for crop producers to use manure as a crop nutrient source, thereby expanding the land base available for manure application. A larger land base provides flexibility in timing manure applications and reduces the tendency to over-apply on a limited amount of land. Recent technological improvements have increased manure-handling efficiency. Large spreader tanks and transport vehicles have been developed, and in-field relay tanks and nurse trucks with boom extensions have improved the effectiveness of over-the-road hauling.

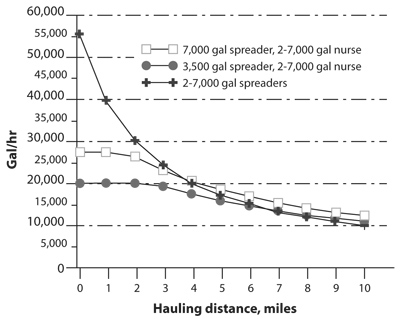

New study Compared with tank spreader/nurse truck systems, tractor-drawn tank spreaders alone are more productive when fields are close to storage because there is no in-field nurse tank-to-spreader transfer, but the hauling rate of tank spreaders declines rapidly as the hauling distance increases. Tank spreader productivity drops by 50 percent with a three-mile haul (Figure 1). Nurse trucks have an advantage with longer hauls because of faster travel speed. Nurse trucks over-the-road typically average about 10 mph faster than high-speed tractors.

What we found Tank spreaders with one-half the volume of the nurse trucks were used to reduce the potential for soil compaction and improve in-field maneuvrability. When one 3,500-gallon spreader was used with two 7,000-gallon nurse trucks the tank spreader had no idle time within 2.6 miles of the pit and the hauling capacity was about 20,200 gallons/hour. Compared with a 7,000-gallon spreader, the 3,500-gallon spreader reduced the hauling capacity by 17 percent with a three-mile haul.

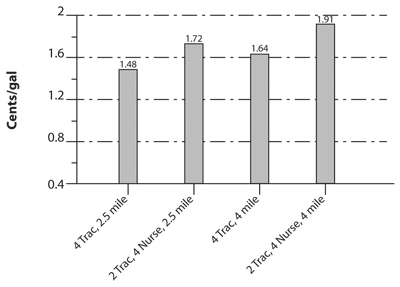

Economics of manure transport using nurse trucks An alternative hauling system used two 9,000-gallon tank spreaders with four 9,000-gallon nurse trucks. The tank spreaders were used for hauling to fields less than three miles from the pit and the nurse trucks were used with the tank spreaders when hauling to fields three or more miles from storage. When hauling to fields near the pit this system cut productivity by one-half, but it improved productivity when hauling to fields three to four miles away. Compared with four tank spreaders, the farm-average hauling rate with the nurse trucks decreased 26 percent to 43,100 gallons/hour. Thirty-one 10-hour days were needed for transport and injection compared with 26, 10-hour days for four tank spreaders. The cost for pumping and agitation was 0.17 cents/gallon for each system. Transport and injection was 1.31 cents/gallon using four tank spreaders and 1.55 cents/gallon using two tank spreaders and four nurse trucks. The total cost for injection using the four tank spreaders was 1.48 cents/gallon, which work out to $129/cow/year. The total cost using four nurse trucks was 1.72 cents/gallon, which works out to $152/cow/year. Transport and land application accounted for about 90 percent of the total cost. The cost of injection was about 10 percent greater than surface broadcast with tillage incorporation. We evaluated the effect of distance on labor and hauling cost by increasing the farm-average hauling distance by 50 percent to four miles with fields ranging from 1.5 to six miles from storage. The longer hauling distance reduced the productivity of four tank spreaders by 13 percent and reduced the productivity of two tank spreaders with four nurse trucks by 11 percent. The labor requirement increased from 26 to 31 days with four tractor-drawn spreaders, and from 31 to 37 days for the spreaders with nurse trucks. The total cost for pumping, agitation, transport and injection for four tank spreaders with the extended hauling distance was 1.64 cents/gallon ($143/cow/year) and 1.91 cents/gallon ($169/cow/year) for the spreader/nurse truck system. Summary Semi-tractor-drawn nurse tanks for over-the-road transport can provide flexibility in scheduling field operations and increase the productivity of tractor-drawn tank spreaders when applying manure to fields more than three miles from storage. Nurse tanks are less costly than tank spreaders. A large nurse tank with hydraulics and a boom extension costs about $25,000 compared to $90,000 for a large tank spreader with an injection unit. Custom applicators have access to the large and specialized equipment needed for timely and cost-effective manure application. A typical hourly charge for custom hire of a large nurse truck is about $100/hour. Custom hire of manure-hauling services may be a good business decision for livestock producers. Tim Harrigan is with the department of Biosystems and Agricultural Engineering at Michigan State University. For more information about the on-farm study and economic evaluation involving custom manure applicators, contact Tim at harriga1@msu.edu or at 517-353-0767. |

|||||||||